Products made from algae are thriving in the maritime sector and biotechnology is one of the most thriving business for maritime startups. Micro-organisms and algae are being used to make lamps, biofuel or new foods. First let’s have a look at what they are that makes algae so spacial.

Algae is a huge group of photosynthetic organisms (that are not necessarily closely related). Algae range from unicellular microalgae, such as Chlorella, to multicellular forms, such as the giant kelp, which may reach up to 50 m in length.

There are hundreds of thousands of species of micro-algae in our oceans and rivers, but just a fraction have been categorised which means there are plenty of opportunities we don’t know about yet. They also produce more more oxygen than the world’s rainforests and absorb more carbon dioxide.

They’ve been used as fertilizers, as an energy source, to create polymers, in laboratories (agar), as gelling agent in foods, as a food, to control pollution (mainly nitrogen and phosphorous), in medicine…

There are plenty of companies working in this field, so let’s have a look at what some of them are doing with algae:

Bio-curtains to absorb pollution from cities

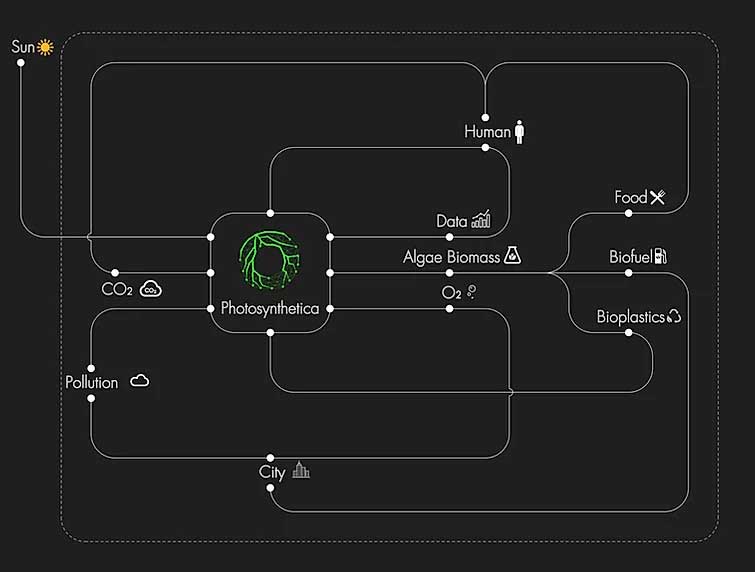

PhotoSynthetica was born from ecoLogicStudio (architects Marco Poletto and Claudia Pasquero). PhotoSynthetica is a photosynthetic system which uses solar energy to remove CO2 and pollutants from the atmosphere and produce a food resource in the form of algae. It’s a biologically active (BIO) and digitally connected (SMART) design, capable of capturing CO2 and evolving into a carbon negative product over its entire life-cycle. It can be used as a building cladding system, a canopy or inside buildings.

CO2 molecules and air pollutants are captured and stored by the algae, thereby enabling the algae to grow into into biomass. The biomass is easily harvested and employed in the production of bioplastic raw material, biofuel, fertilizers and super-food. To culminate the process, freshly photosynthesized oxygen is released at the top of each facade unit of PhotoSynthetica into the urban microclimate or the building interior.

Home grown algae

Another product made for interior design is The Coral: an indoor micro-algae farm, developed by Hyunseok An. This wall-mounted bioreactor proposes a daily ritual for algae consumption through home algae farming activities.

Each culture cell in the four-by-four grid wall frame contains around 2 g of algae when it turns dark green—the recommended daily intake amount. The 16 cells in the farm enable the growth and consumption of algae every day because one cell has a biweekly cycle to replenish after harvesting.

Biodegradable algae-based plastics

A home-compostable alternative to plastic film has recently won the James Dyson Award. MarinaTex is a versatile material that can be an alternative to plastic in a variety of applications. It’s made from agar from red algae and proteins from fish processing waste.

The product was developed by Lucy Hugues, a 24-year-old student from the University of Sussex in the UK, and the result is a translucent, strong, odorless and flexible sheet that looks a lot like the plastic we are familiar with. The material degrades completely after 4 to 6 weeks.

Clothing

Designer Charlotte McCurdy has fashioned a water-resistant jacket from a bioplastic made of algae. This design won the 2019 Innovation by Design Awards in the Experimental category.

The algae are bound together by heat and finally poured into moulds which are custom-made to ensure the plastic survives the curing process.

Once solidified, the algae plastic is given a thin coating of wax to improve its resistance to water.

Carbon capture farms

Another company that has a product to capture CO2 with algae is Pondtech, that designs and operates scalable bioreactors that use industrial greenhouse gases to cultivate algae. The products they obtain are vegan supplements (Spirulina and Chlorella), animal feed with up to 70% protein content and a rich amino acid profile, and raw materials for industrial products such as bioplastics, biofuels, cosmetics…

Algaenergy

Currently AlgaEnergy has products and solutions, based on different microalgae, for industries such as agriculture, nutrition (both human and animal), cosmetics and aquaculture, and they are studying the application potential for the pharmaceutical industry, in obtaining biomaterials or biofuels. This company won the People’s choice award at the BlueInvest Day 2020.

Algaenergy’s R&D project portfolio ranges from genetic engineering applied to the modification of certain microalgae’s metabolism to the development and implementation of new and more efficient systems for cultivation and processing of microalgal biomass. They also participate in international R&D projects with a total investment of more than EUR 77 million.

Bio-fuel

At Synthetic Genomics (SGI), they’re using algae to produce biofuels that recycle the atmosphere’s excess amounts of CO2. Even though microalgae are better at converting CO2 and sunlight into biomass, compared to land-based crop plants like oil palm, sugar cane or corn.

Still, there are some challenges that must be worked out before we can use microalgae to make fuel: microalgae, while having impressive productivity, are not economical due to the comparatively high costs of algal farm installations and processing. But with advancements in genome sequencing, bioinformatics and precise gene editing technologies, improving algae’s productivity is now becoming a reality.

In 2019, SGI’s collaboration with ExxonMobil (they’ve been working together since 2009) goes outdoors with the implementation of the California Advanced Algae Facility (CAAF). This outdoor field study is helping scientists understand how to scale algae biofuels for potential commercial deployment. The hope is to reach the technical ability to produce 10,000 barrels of algae biofuel per day by 2025. This will signal a key engineering milestone for large-scale production of algae biofuel.