How can we design ship engine rooms that cater better to the needs of their human operators? How can we do this through a design process that involves multiple companies and competences? We facilitated a human-centred, collaborative design process together with the ship design company Ulstein and the engine systems integration company PON Power.

Ship design is a decision-making process and communication is one of the main design activities. As such, there is a need to secure undistorted communication and equal roles in the dialog among stakeholders of the ship design process. The facilitation of information sharing between design stakeholders is also important for exploring innovation opportunities lying at the crossover points between different design steps executed by different design stakeholders.

The traditional approach is that a subcontractor delivers a detailed design proposal that is included in the overall ship design concept by the ship design company. In terms of the design of engine rooms and engine control rooms on ships, we uncovered the following challenges with this approach with the ship design company Ulstein and the engine systems integration company PON Power:

- PON Power needs to integrate many different systems into a coherent and compact engine room without the possibility of being able to modify any of the integrated systems.

- The technical drawings need to be shared as fast as possible with Ulstein so that they can start integrating this part of the ship with the rest of the ship.

- Even when the final technical drawings are very detailed, the shipyard will need to add more systems during the construction phase, which might impact the original design quality.

To address these challenges, we implemented a three-step process. First, the field study focused on PON Power’s part of the ship design process, with the objective being to better understand the experience of their end users working in the engine rooms: How can we design for better experiences of ship engine rooms?

Then, the post-field study workshop focused on how PON Power and Ulstein could collaborate when designing a ship with an engine room that would cater for the needs of the ship’s crew and how they could secure the quality of the design all the way up until the delivery of the ship.

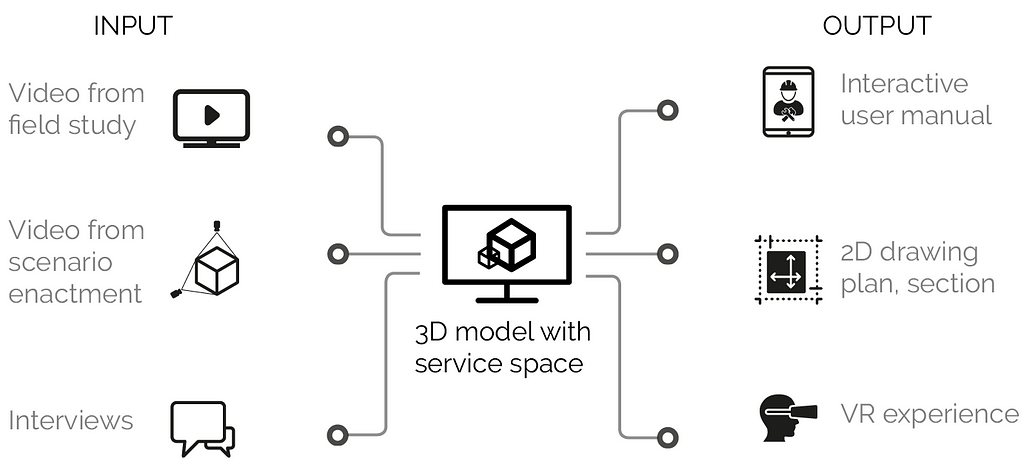

Finally, in the prototyping session, we tested a concept that was generated during the field study and the workshop that had the potential to improve the design process through the modelling of operational use-scenarios in a 3D CAD model.

The field study

To prepare for the field study, we started by visiting PON Power’s office and engine systems integration site. We learned how PON Power worked, and what information from the field they were interested in. Then, one researcher from OICL spent five days on board a platform supply vessel designed by Ulstein and built in China with an engine room designed by PON Power. The field observations focused on:

- The tasks performed by the crew in the engine room during the supply operations of the ship.

- The systems used to perform these tasks.

- The experiences of the crew when using these systems.

As a result, we identified two main problem areas:

- The engine as a working place: The engine needs to be seen as the central element of a working place where human operators need to carry out work tasks every day.

- Engine integration in the engine room: The engine’s integration into the whole engine room needs to enable the human operators to carry out their work tasks in the safest and most efficient way.

The post field study workshop

We then facilitated a workshop with PON Power and Ulstein to explore their own experience in the design of engine rooms and their integration into the overall ship design. We identified design problems that repeatedly came up during the design of engine rooms and sketched opportunities for addressing these problems.

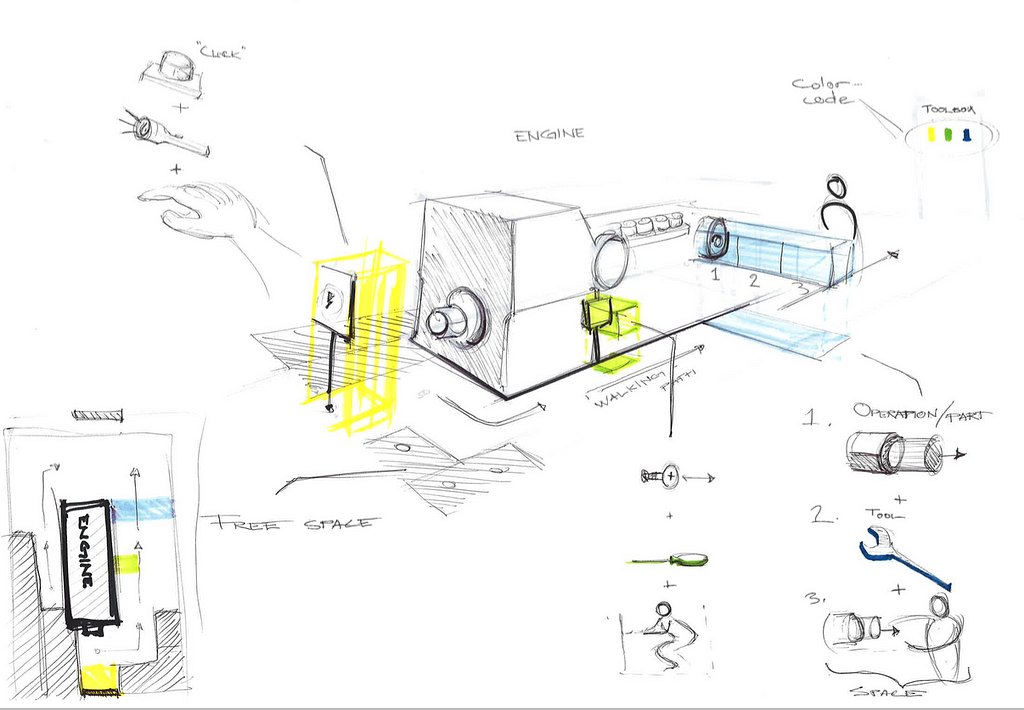

Before the workshop, we prepared visual concepts that summarised the ideas generated during the field study. The visuals helped in facilitating the workshop conversations and triggering improvements and new ideas.

There were two main outcomes of the workshop. First, a common understanding was reached of the engine room design requirements built upon the perspective of the end users and the design stakeholders in their respective contexts of use. Second, a concept emerged for a collaborative de- sign process and a collaborative format supporting this process.

Prototyping

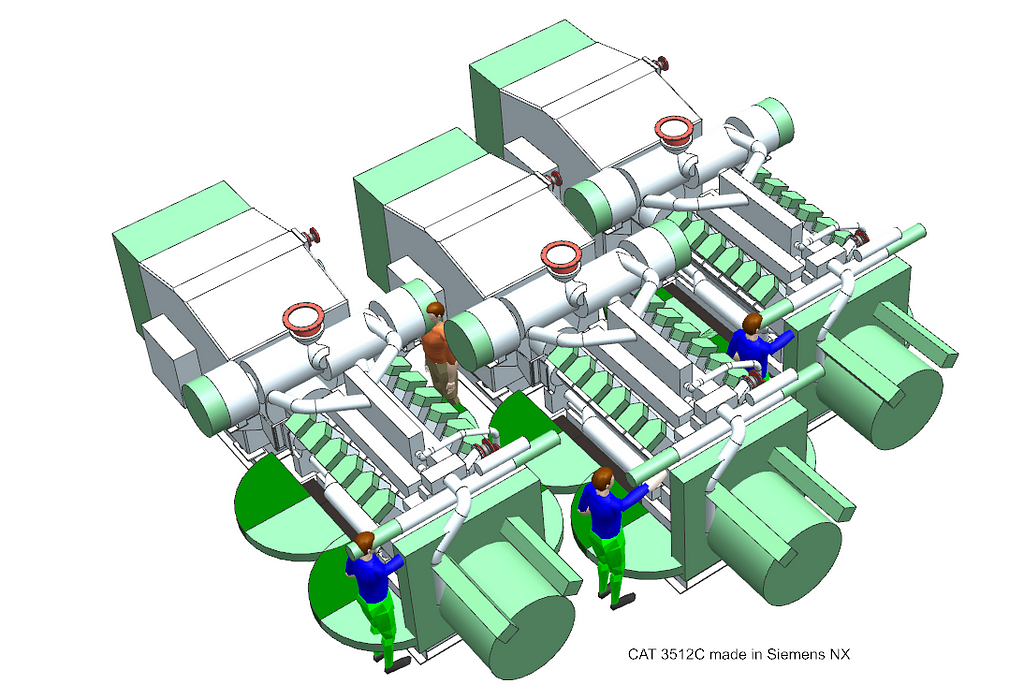

We went back to PON Power’s office to prototype the concept for a collaborative, human-centred design approach to engine room design. We filmed one of PON Power’s service mechanics while he performed service interventions on an engine. We found and built mock-ups that reproduce the sizes and shapes of different engine parts and servicing tools.

This enabled us to document in video and then transfer onto a 3D CAD model how a service intervention is done, what tools are used and what space is required around the engine for the mechanic to work under safe and optimal conditions.

Potential impact

The concept of human-centred engine rooms that was developed in this case has the potential to enable more efficient maintenance and service interventions for the end users of the engine rooms, which reduces the risks of injury, system failure and operational downtime.

For the design stakeholders involved, the use of human-centred design methods has the potential to improve the detection of design flaws and, con- sequently, to reduce the risk of additional design iterations to correct these flaws.

The design process itself enabled each company to stimulate internal and external collaboration. With PON Power, we connected a service mechanic with a 3D modelling engineer, a yard supervision engineer and the technical director. With Ulstein, we connected concept engineers working with machinery and hull design with engineers working with detailed ship design. Last but not least, we connected all these design stakeholders together with the end users of their design artefacts.

Authors: Etienne Gernez and Kjetil Nordby

Further reading: Conference article “Human-centered, collaborative, field-driven design — a case study”

The project is done in collaboration with Ulstein International, Pon Power and DNV GL and funded by the Norwegian Research Council in the MAROFF program. Project number: 269494

OICL is a research group at the Oslo School of Architecture and Design.

Field study case: design of ship engine rooms was originally published in Ocean Industries Concept Lab on Medium, where people are continuing the conversation by highlighting and responding to this story.